Up to now, the standard in hard chrome plating has been lead anodes. They deliver sufficient, if not overly impressive, results and are comparatively cheap to...

The most efficient and eco-friendliest solution for hard chrome plating

Up to now, the standard in hard chrome plating has been lead anodes. They deliver sufficient, if not overly impressive, results and are comparatively cheap to procure.

However, the market’s requirements for anodes have changed, and decision makers in electroplating have adopted a more long-term approach: quality must be exceptional in a hotly contested mass market, while costs shouldn’t get out of hand over the years, and constantly increasing environmental regulations have to be fulfilled.

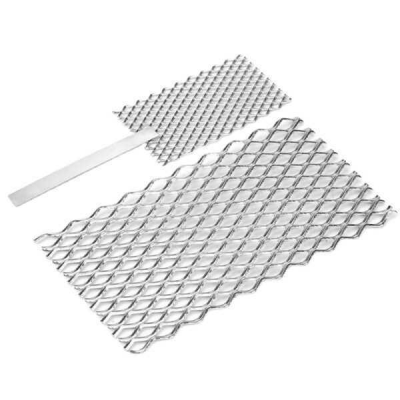

That’s why PLATINODE® (refractory metals such as titanium and niobium coated with pure platinum in molten salt) isn’t just an alternative to previously standard lead anodes, rather the most efficient solution. And not just in terms of quality and environmental aspects - but also economy. A significantly longer lifespan and the possibility of re-plating are just two reasons why lead anodes lose their last advantage of lower procurement costs after around three years. A personal, no-obligation comparison calculation will win you over.

Advantages

Quality Benefits

Best possible coating quality

Possible to create complex shapes

Durable and dimensionally stable

Cost Benefits

Long lifespan (procurement price pays off)

Cheap re-plating (can be re-used several times)

No production downtime due to maintenance

Energy saving (better conductivity)

Environmental Benefits

No toxic lead chromate sludge as a byproduct

Increased safety thanks to lighter weight

Applications

Shock absorbers

Compression rolls

Piston rings/rods

Hydraulic cylinders

Rod material